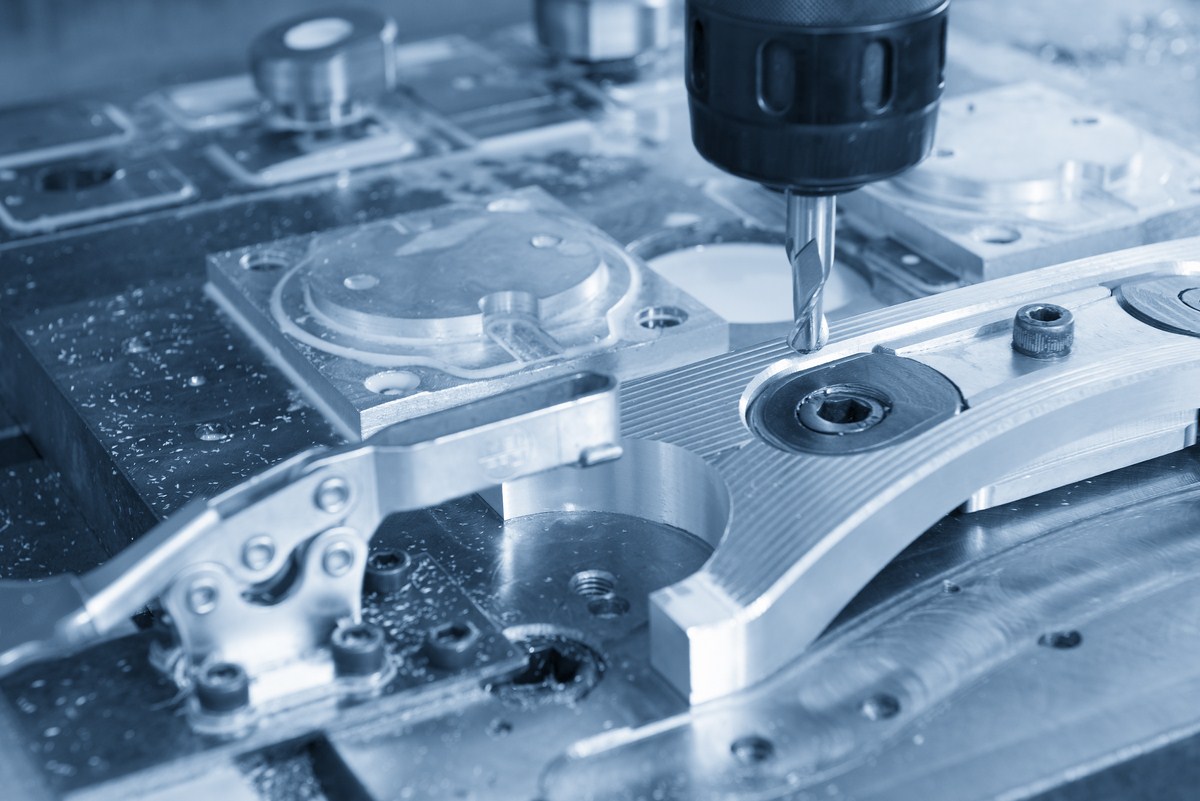

PRECISION MACHINING

In the field of precision machining, it is important to break sharp angles and round off the edges. Treatment in deburring tumbler makes this operation possible, along with degreasing and homogenising the surface. The processing is done in bulk, so there is no need to clamp down the part. A removable partition system allows the tumbler's tank to be compartmentalised to avoid any impacts between the parts.

- Edge rounding

- Breaking of sharp angles

- Degreasing

AERONAUTICS

Finishing in the aeronautics industry, whether it is deburring or edge rounding, is governed by standards and procedures. Having extensive experience in this field, SPALECK INDUSTRIES is able to provide a reactive and reliable technical response while meeting the manufacturers' normative requirements.

- Edge rouding

- Breaking of sharp angles

- Degreasing

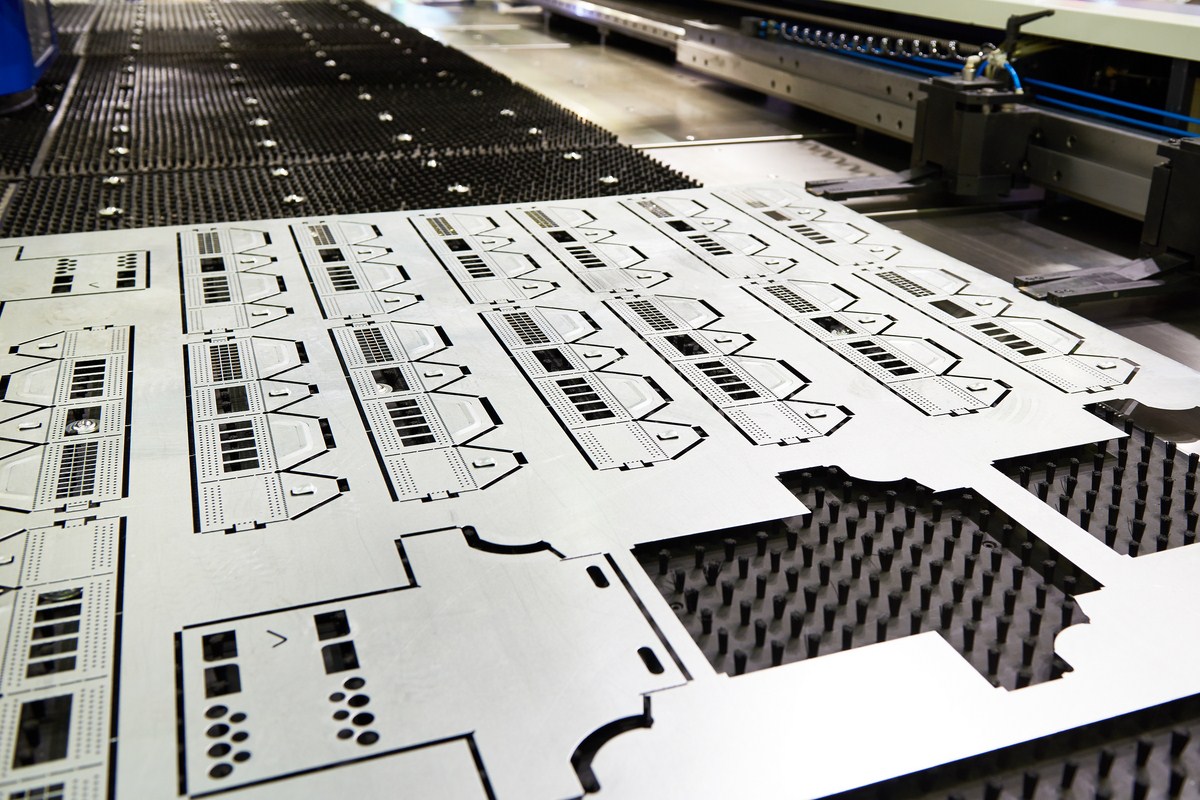

THIN SHEETMETAL WORK

Produced from laser cutting, punching or stamping operations, thin sheetmetal parts have sharp edges and burrs that must be eliminated through treatment solutions that require little maintenance and are particularly adapted to the turning over of the parts and the material (copper, titanium, aluminium, etc.)

- Edge rouding

- Breaking of sharp angles

- Deburring

METALWORKING

Whether it is a matter of stripping, descaling or deburring, the deburring tumbler treatment eliminates the need for constraining grinding operations and optimises welding operations.

- Deburring

- Stripping

- Descaling

STRUCTURAL STEELWORK

The structural steelwork sector has been in compliance with standard EN 1090 for several years. This standard requires framework builders to guarantee parts against corrosion by rounding off the edges and to descale the parts prior to welding. The deburring of gussets, plates and railings in a tumbler system allows the desired surface finish to be obtained while maintaining the traceability of the parts, even when identified with an Ecrimetal metal marking pen.

- Deburring

- Descaling

- Breaking of sharp edges

MACHINERY MANUFACTURE

Agricultural, railway and construction machinery are applications in which parts are produced in large series and are generally of medium and high thickness. SPALECK INDUSTRIES' various solutions are adapted to these requirements.

- Deburring

- Descaling

- Deoxidation

FURNITURE

Street furniture requires special deburring to ensure the safety installers and users (without risk being cut by sharp edges). Aesthetics plays an important role in this type of finish.

- Edge rouding

- Breaking of sharp angles

- Deburring

POWDER COATING / SURFACE TREATMENT

Before powder coating, treatment in the deburring tumbler allows the part to be cleaned to ensure that the paint adheres properly. When the painting operation is completed, and to maintain this environmental aspect, the deburring tumbler also makes it possible to strip the paint off the swing hooks and to do away with a costly and chemical treatment.

- Stripping

- Deburring

- Degreasing